The diameter of cables in electrical installations is very important. It affects how well the system works and how safe it is. The Tech 2/3 armored cable is one type that often gets asked about. What size is it, and why does it matter? We’ll look into the details of Tech 2/3 armored cable sizes, why they vary, and the need for correct conduit sizes.

What is the Diameter of a Tech 2/3 Armored Cable?The diameter of a Tech 2/3 armored cable (also known as TECK90) is approximately 1.091 inches (about 2.79 cm) for the outer diameter.

Key Takeaways

- Understanding the diameter of Tech 2/3 armored cable is crucial for proper installation and safety.

- Cable size is influenced by factors like conductor material, insulation thickness, and armoring.

- Industry standards provide guidelines for armored cable dimensions to ensure compatibility and compliance.

- Proper conduit sizing is essential when working with armored cables to accommodate the cable diameter.

- Knowing the relationship between cable gauge and diameter can help with electrical project planning.

Understanding Armored Cable Diameters

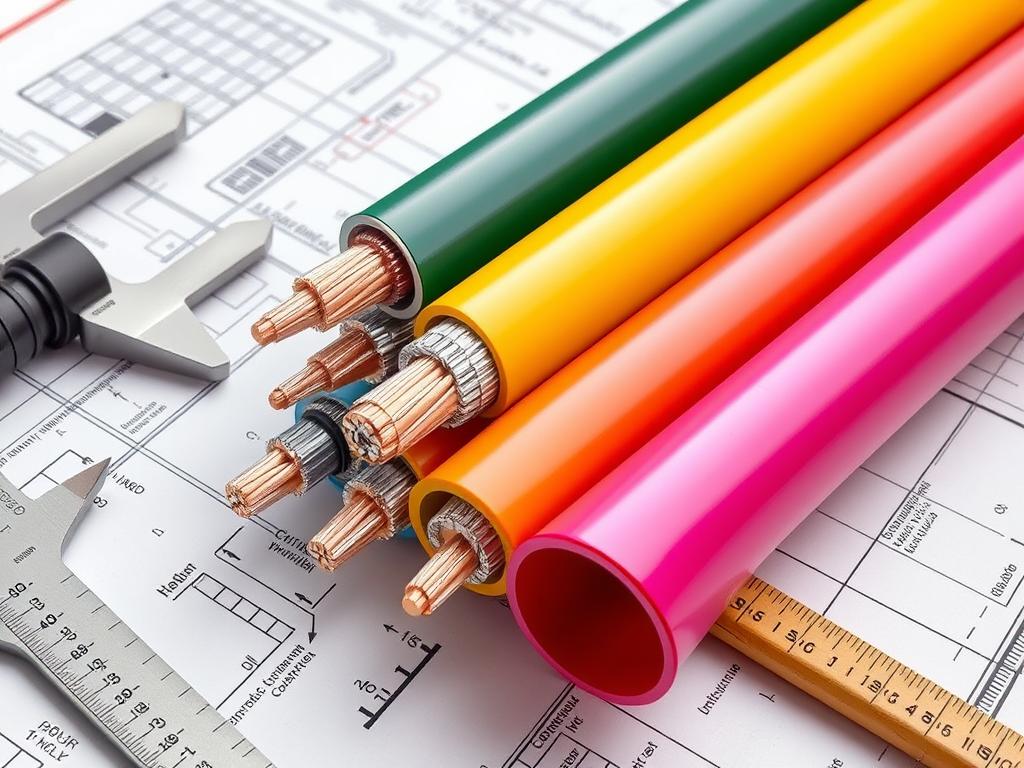

When we talk about electrical installations, cable dimensions and armored cable specs are key. The cable’s size, or diameter, impacts its physical properties and fit in conduits and boxes. Let’s look into why cable size is important and what affects an armored cable’s diameter.

Why Cable Size Matters

The diameter of an armored cable is crucial for a few reasons. It determines how much current the cable can carry. Larger diameters can handle more current. Also, the cable’s diameter affects its flexibility and installation ease. Thicker cables are harder to route through tight spaces.

Factors Influencing Cable Diameter

The diameter of an armored cable is shaped by several factors, including:

- Conductor size: The size of the electrical conductors inside the cable impacts its diameter.

- Insulation thickness: The insulation material’s thickness around the conductors adds to the cable’s size.

- Armoring specifications: The type and thickness of the armoring layer, which protects the cable, also affect its diameter.

- Number of conductors: Cables with more conductors will generally have a larger diameter than single-conductor cables.

Knowing these factors is vital when picking the right armored cable for your project. It ensures a safe and efficient electrical setup.

What is the Diameter of a Tech 2/3 Armored Cable?

The diameter of a tech 2/3 armored cable can change based on who made it and how it’s built. Generally, these cables are between 0.5 inches (12.7 mm) and 1.25 inches (31.75 mm) thick. This size matters because it affects how well the cable fits and works with different setups.

To find out the exact size you need, check the specs from the maker or talk to an expert. This helps you pick the right cable size for your job. It also prevents any problems later on.

“Knowing the exact cable diameter is crucial for proper installation and ensuring a secure, reliable connection.”

Knowing the usual size of a tech 2/3 armored cable helps you choose the best one for your needs. Remember, getting the details right is key to a successful project.

Cable Dimensions and Specifications

Armored cables, like Tech 2/3, follow strict industry standards. These standards cover cable size, thickness, and area. Knowing these specs helps pick and install the right armored cables for your project.

Industry Standards for Armored Cable Sizing

Groups like the National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC) set these standards. They ensure armored cable specifications and wire and cable diameters are consistent. This guarantees quality and performance.

Some key standards for armored cable sizing include:

- NEMA WC 70/ICEA S-95-658 for power cables

- NEMA WC 71/ICEA S-96-659 for communication cables

- IEC 60228 for conductor cross-sectional areas

- IEC 60502-1 for power cable dimensions

Following these standards means armored cables, like Tech 2/3, are safe and reliable for many uses.

| Industry Standard | Specification | Relevance |

|---|---|---|

| NEMA WC 70/ICEA S-95-658 | Power cable specifications | Defines guidelines for power cable dimensions, including armored cables |

| NEMA WC 71/ICEA S-96-659 | Communication cable specifications | Outlines requirements for communication cable dimensions, including armored cables |

| IEC 60228 | Conductor cross-sectional areas | Establishes standards for the cross-sectional area of conductors, which impacts cable diameter |

| IEC 60502-1 | Power cable dimensions | Provides guidelines for the overall dimensions of power cables, including armored cables |

Knowing these standards helps pick the right armored cable specifications and wire and cable diameters for your project.

Conduit Sizing for Armored Cables

Working with armored cables means you need the right conduit size. The size of the conduit is key for the cable’s fit and safe installation. I’ll show you how to pick the right size for your Tech 2/3 armored cable project.

The conduit size should match the cable’s outside diameter. A good rule is to make the conduit’s inside diameter 25% bigger than the cable’s. This extra space helps the cable slide through without getting damaged.

| Armored Cable Diameter | Recommended Conduit Size |

|---|---|

| 0.5 inch | 3/4 inch |

| 0.75 inch | 1 inch |

| 1 inch | 1.25 inch |

| 1.25 inch | 1.5 inch |

Remember, the conduit size must also fit any extra wires or cables. If you’re installing multiple cables, add up their total area. This will help you choose the right conduit size.

Choosing the right conduit sizing for armored cables avoids installation problems. It keeps your electrical system safe and your cables in good shape for a long time.

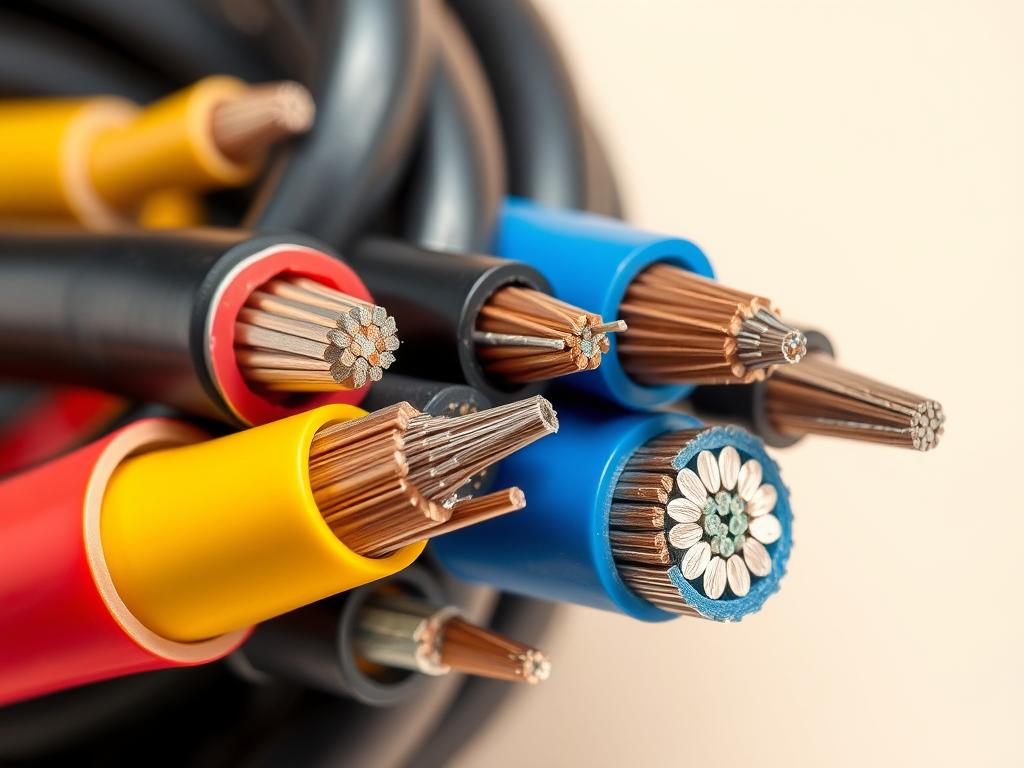

Wire and Cable Gauges Explained

It’s key to know how electrical cable gauge and wire diameters are linked, especially with armored cables like Tech 2/3. The gauge system measures wire or cable thickness. It shows the cable’s size directly.

The Gauge System Explained

The gauge system works in reverse. A lower number means a bigger wire or cable. For instance, a 10-gauge wire is thicker than a 12-gauge one. This makes picking the right cable size easy.

The gauge and diameter relationship isn’t straightforward. It’s more like a logarithmic scale. As the gauge number goes up, the diameter goes down a lot. Knowing this is vital for choosing the right cable size for your project. The cable’s size affects installation, how much current it can carry, and conduit size.

| Gauge | Diameter (inches) | Diameter (mm) |

|---|---|---|

| 10 | 0.1019 | 2.59 |

| 12 | 0.0808 | 2.05 |

| 14 | 0.0641 | 1.63 |

| 16 | 0.0508 | 1.29 |

This table shows how gauge and diameter are connected for some common cable sizes. It’s clear that choosing the right gauge is crucial for your project’s needs.

Electrical Cable Thickness Considerations

When working with armored cables, the thickness matters a lot. It affects flexibility, weight, and how well the cable can cool down. These are key things to think about for any electrical setup. I’ll explore how the thickness of Tech 2/3 armored cables can affect your project.

Thickness affects how flexible a cable is. Thicker cables are harder to bend and fit in tight spots. This is a big problem in places where space is tight, like homes or offices. Thinner cables are more flexible but might break or bend easily during setup.

The weight of the cable is another big deal. Thicker cables are heavier, making them harder to handle, especially when hanging or running vertically. This extra weight can also stress the structures holding the cable, like trays or conduits. This might mean you need stronger and more expensive setups.

Lastly, the thickness affects how well the cable can cool down. Thicker cables have less surface area to release heat. This is a big issue in setups with lots of power or density. Overheating can cause problems like reduced performance, wear, or even fires.

| Thickness Consideration | Impact |

|---|---|

| Flexibility | Thicker cables are less flexible, making them more challenging to route in tight spaces. |

| Weight | Thicker cables are heavier, which can create installation challenges and stress on supporting infrastructure. |

| Heat Dissipation | Thicker cables have a lower surface area-to-volume ratio, potentially impeding heat dissipation. |

Knowing about the thickness of Tech 2/3 armored cables helps you make better choices. This ensures your electrical system works well and lasts a long time.

Armored Cable Applications

Tech 2/3 armored cables are great for many electrical uses. They work well in homes, businesses, and factories. These cables are tough and last long, perfect for places where they might get damaged or face harsh conditions.

When to Use Tech 2/3 Armored Cables

Here are some situations where tech 2/3 armored cables are best:

- Residential construction – They’re great for new homes or when fixing up an old one. They keep the power flowing and protect against damage.

- Commercial buildings – In places like offices, stores, or warehouses, these cables ensure the electrical systems are safe and work well.

- Industrial facilities – In factories, where cables might get hurt easily, tech 2/3 armored cables keep important power and control systems safe.

- Outdoor installations – Their strong build makes them perfect for outside use. This includes lights, security systems, or temporary power setups.

- Underground or buried applications – They’re made to handle the tough conditions of being underground. They protect against soil, water, and other outdoor factors.

Choosing the right tech cable size and armored cable specifications is key. It makes sure your electrical setup is safe, reliable, and lasts a long time, no matter the project or setting.

Conclusion

In this article, I’ve covered the diameter and specs of Tech 2/3 armored cable. You now know how cable size is determined and the importance of following industry standards. This knowledge helps you make smart choices when using this cable.

The size of a Tech 2/3 armored cable is key. It affects how well it fits with electrical gear and safe installation. I’ve talked about wire and cable gauges and thickness to guide you through the armored cable world.

Always check the manufacturer’s advice and talk to a pro if needed. This way, your electrical projects will be a success. With what you’ve learned, picking the right Tech 2/3 armored cable is easier. You’ll also ensure your installation is safe and meets all standards.

FAQ: What is the Diameter of a Tech 2/3 Armored Cable?

What is the typical diameter range for a Tech 2/3 armored cable?

Tech 2/3 armored cables usually range from 0.5 inches to 1.25 inches in diameter. But, the exact size can change based on the maker and how it’s made.

Why is cable size important?

Cable size matters because it impacts its flexibility, weight, and how it handles heat. It also ensures the cable fits right in conduits and boxes, which is key for safety and function.

What factors influence the diameter of an armored cable?

Several things can affect an armored cable’s diameter. These include the number and size of conductors, the armor and insulation thickness, and the making process.

What industry standards are used for armored cable sizing?

Armored cables, like Tech 2/3, follow industry standards. These standards give guidelines for dimensions like diameter, thickness, and area.

How do I determine the correct conduit size for an armored cable?

To find the right conduit size, look at the cable’s diameter. Make sure the conduit can hold the cable securely. Use industry guidelines and get advice from a pro for your Tech 2/3 cable.

How does cable gauge relate to the diameter of a wire or cable?

Cable gauge is linked to a wire or cable’s size. A higher gauge means a smaller diameter, and vice versa. Knowing this is key for picking and installing the right cable.

What are the thickness considerations for armored cables?

The thickness of an armored cable, along with its diameter, impacts its flexibility, weight, and heat handling. Choosing the right thickness is crucial for the cable’s performance and fit in your project.

When is the use of a Tech 2/3 armored cable appropriate?

Tech 2/3 armored cables are great for many electrical jobs. They’re good for homes, businesses, and factories. They’re especially useful where you need extra protection against damage, moisture, or corrosion.